Wieland Randall is committed to maintaining operational excellence by identifying key processes and establishing quality objectives that we monitor; believing this helps drive continuous improvement in our pursuit of worldwide customer satisfaction.

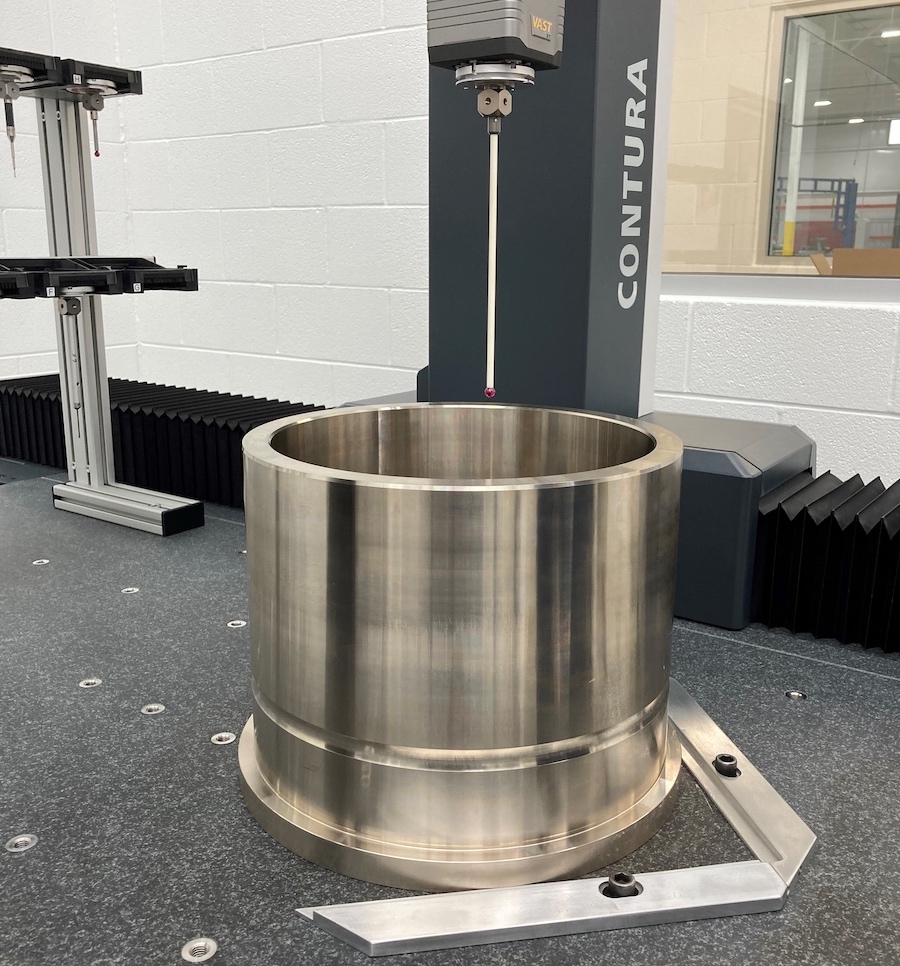

What is Quality? Wieland Randall strives to understand exactly what quality means to every one of our customers. Randall has the flexibility to build a program that exceeds the unique needs and requirements of each individual customer. At Randall we use reliable gauging and inspection frequencies to ensure the results of all measurements throughout the manufacturing process meet our customer’s expectations. Randall has 3 Zeiss Prismo bridge type CMMs that utilize the latest Calypso programming software in a temperature-controlled inspection lab where all final inspections are performed before product is released for shipment. Along with the CMMs, Randall uses many traditional gauges and techniques to perform measurements and verify quality control throughout the manufacturing process. As an ISO 9001 certified company, quality is the culture of every employee.

What is Quality? Wieland Randall strives to understand exactly what quality means to every one of our customers. Randall has the flexibility to build a program that exceeds the unique needs and requirements of each individual customer. At Randall we use reliable gauging and inspection frequencies to ensure the results of all measurements throughout the manufacturing process meet our customer’s expectations. Randall has 3 Zeiss Prismo bridge type CMMs that utilize the latest Calypso programming software in a temperature-controlled inspection lab where all final inspections are performed before product is released for shipment. Along with the CMMs, Randall uses many traditional gauges and techniques to perform measurements and verify quality control throughout the manufacturing process. As an ISO 9001 certified company, quality is the culture of every employee.

Randall’s Quality Management System is driven by the customer’s objectives. We believe this adds value to the relationship we build for each company with which we partner. When customers evaluate their supply chain, value is an important part of that process. Randall brings that value through the entire customer experience. Traditional quality activities focus solely on manufacturing. Randall believes to obtain “quality,” it is required in all the functions of our organization. Randall Bearings is Quality, Value, and Customer Experience.

- ISO 9001

- FMEA / pFMEA

- Manufacturing control plans

- Inspection control plans

- PPAP - Level 1, 2, & 3

- SPC

- Gage R&R

- Cpk / Ppk

- Lean manufacturing principles

- 6s Practices

- Continuous improvement plans

- GD&T