1906 to the 1980's

With its beginnings going back to 1906, 1918 marks the year that Randall Graphite, Inc. became a Delaware corporation doing business in Chicago, Illinois.

In the mid-1930s Randall developed the graphite lubricated Pillow Blocks and began a growth cycle that continued until the end of World War II. The use of graphite to supplement oil in the lubrication of sleeve bearings had become the norm and Randall needed more room if growth was to continue.

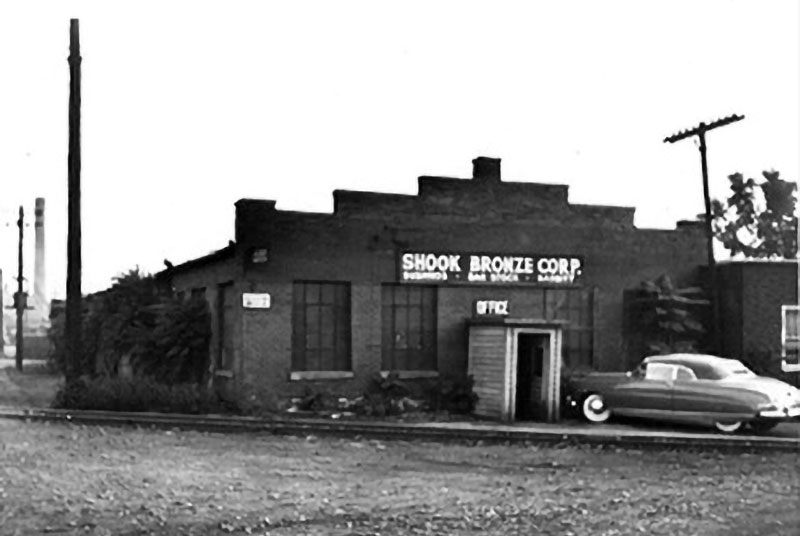

In 1949 Randall purchased the assets of Shook Bronze in Lima, Ohio and moved all manufacturing from Chicago to Lima. The name of the company was changed to Randall Graphite Bearings, Inc. This move provided Randall with a sand and centrifugal foundry and another growth period followed.

In 1965 the name was changed to Randall Bearings, Inc., as it is known today. Randall remained a strong force in the Bronze Bearing industry throughout the 1970s and continued to grow and prosper.

The early 1980s were difficult years for American foundries and Randall made the decision in 1985 to close all foundry operations and to concentrate on improving the machining end of the business.

1990 to Present Day

Through the 1990s, Randall transitioned over to a mainly all CNC machining facility, exclusively in Lima, Ohio. Randall settled into a 90,000 square-foot manufacturing and distribution center that also housed the corporate offices.

The completion of a quality control lab in 2000 has placed us in a superior position to continue our growth and to expand into new markets in the coming years.

April 12, 2004, Randall Bearings became ISO 9001:2000 certified. This certification laid the ground work for Randall to gain global recognition as truly a “world class” machining facility.

In 2006, Randall opened a state-of-the-art machining facility in Coldwater, Ohio. This additional facility was designed to complement Lima’s capabilities by specializing in the “fluid power motion industries.” This expansion also provided alternative solutions to customers looking for dual sourcing security in product availability.

On May 20, 2009, Randall Bearings became ISO 9001:2008 certified.

In 2012, Randall again expanded our manufacturing capacities in Lima and Coldwater in response to several significant growth opportunities. Randall made a number of major investments into technologically advanced CNC machines in both plants. These lathes and mills were designed to expand our proficiency into not only the gas and oil business but also to increase our overall part dimensions capabilities while strategically utilizing robotic technology within the production process. The Coldwater facility also increased its manufacturing space by doubling the size of the original facility to 48,000 square feet. The company also transitioned its domicile from the state of Delaware to Ohio.