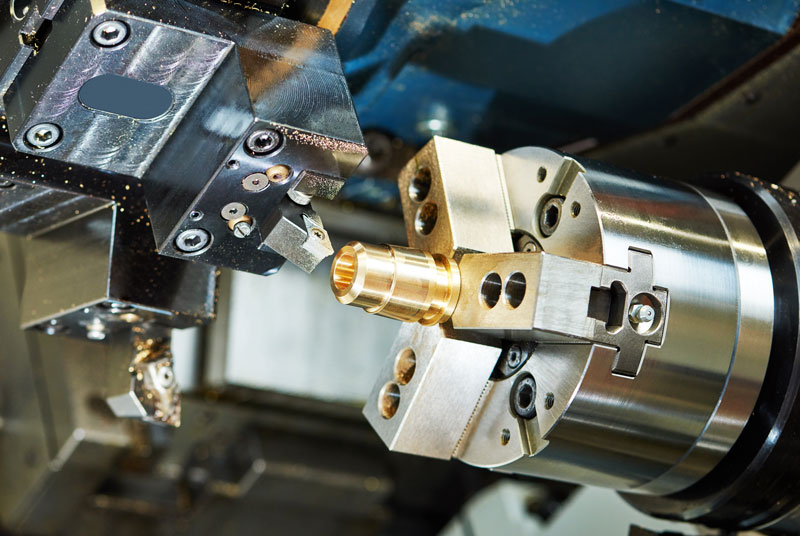

Machining capabilities

Wieland Randall is a machined parts manufacturer with fabrication and tool room capabilities. We specialize in everything from high-volume production runs to sample run offs and prototyping. Our two locations provide 130,000 square feet of climate-controlled manufacturing space. We are committed to an ongoing investment in production equipment, manufacturing facilities, test equipment, and logistical management. We continue to be an innovator in the industry.

Our Ohio facilities in Lima and Coldwater are equipped with machines with a wide range of capabilities to meet any of your machining needs. State-of-the-art computerized CNC multi-axis lathes enable turning and boring simultaneously to ensure the greatest efficiency. CNC lathes are equipped with bar feeders, live tooling, robotic loading, and other automation. CNC dual pallet machining centers allow greater capabilities in the drilling and milling areas to produce more cost-efficient machining processes. Robotic technology is strategically utilized to assist our operators in streamlining the production process. Randall combines quality in craftsmanship with computerization of the machining processes.

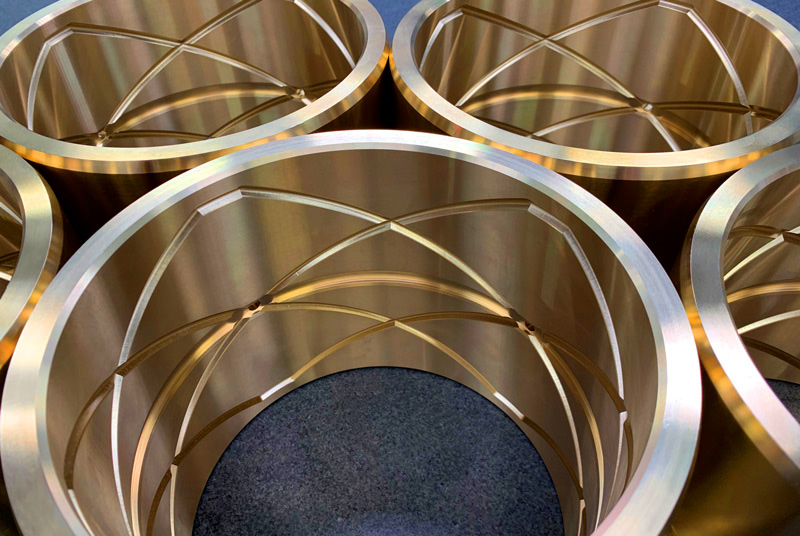

Grooving

Standard Randall Groove Styles fulfill most requirements. Special designs or combinations can be provided if desired.

Click here to view standard groove patterns. Please contact Randall Bearings for assistance on special groove requirements.

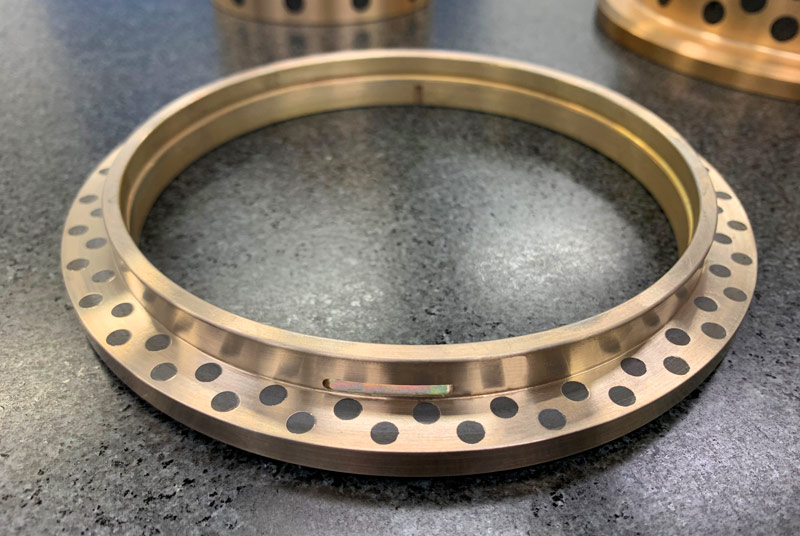

Graphiting

Randall offers graphite fill on all groove styles and drilled hole parts.

Graphite fill is used in grooves and drilled holes for its self-lubricating properties. Graphite fill is a perfect fit for bushings that see intermittent use or are utilized in a low-speed environment where the RPMs necessary for an oil film to form are not present. Graphite also works well in high-RPM environments as it will provide lubrication during start up and shutdown and during sudden shock load situations.

Click here to view standard graphite patterns. Please contact Randall Bearings for assistance on special graphite requirements.